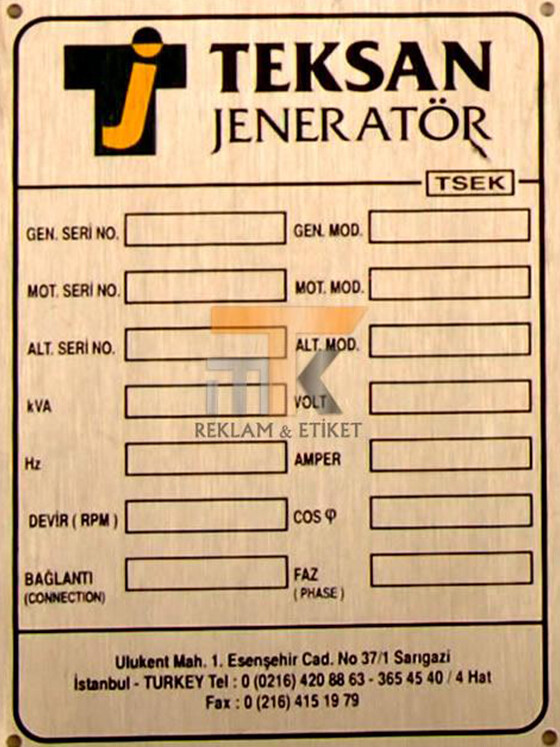

The Metal Label process starts with the graphic work on the metal on which the label is desired to be applied and working according to its dimensions. Then the printing process to be applied on metal sheets is started. If you prefer to screw your metal labels, the final cutting is completed by making holes. Metal labels are made ready to be mounted on their places. Metal Label is applied in many sectors from furniture to warning signs, from factories to the identification of machines. And thanks to its durability for many years, it is getting popular day by day with new usage areas.

The deterioration of advertising tools showing the name of the product or the name of the company means that the name of the company is forgotten. There is no such situation in the metal label method. The reason why it is the most preferred method in advertising works is that its durability continues for a long time. Widely used in terms of brand awareness, the method consists of writing your company name or the name of the product on metal plates such as aluminum. The types of paint used to engrave letters are indelible. Metal plates are prepared using materials such as stainless steel or chrome. With the letters in the color and size you want, the text to make your company the pioneer of its sector and to be engraved in the memories is written. You can make single color or multiple color combinations according to your request. Metal labels are not only easy to make but also easy to install. Different sizes can be produced. If you want, embossing technique is used in inscriptions. It is resistant to all weather conditions. It maintains its durability longer than other advertising products. Resistant to heat and cold, the product does not deteriorate immediately. Any information you want can be written on the metal plate. It is less fragile than other labels used in the market. It is one of the most impressive ways in the field of advertising. Since the material used in the advertising phase will reflect the prestige of your company, it is useful to choose the product from first class materials.

Metal Label Products

Metal label products are very diverse. They are produced by applying different techniques to various materials from aluminum, brass, stainless steel to copper. These are;

- These are Aluminum Label is usually produced in thicknesses between 0.30 mm and 3 mm. The raw aluminum plate is made suitable for label printing by high micron anodizing or just anodizing. Labels made from aluminum, which is a soft metal, are the most preferred type of labeling by the machinery industry, furniture, automotive electronics sectors. It is especially used to identify machinery and device at the customs, which is mandatory for Turkish exporters.

- Stainless Steel Label is produced from stainless steel plates known with AISI 304, AISI 316 and AISI 430 quality grades. The thickness of the labeling plates is 0.30 mm. It can be made up to 5 mm. There are 3 different stainless label surfaces. These are matt, semi-gloss and full gloss. Stainless labels are mostly seen on machines and office decoration materials. The prints to be applied on these labels are in the form of UV printing, screen printing, Acid Etching Label and laser engraving.

- Brass Label is the one that is generally used for visual purposes. It is very common in direction signs, corporate offices, warning signs. Thicknesses from 0.1 mm to 5 mm are preferred in Brass Labels. You can also see brass labels in artistic works.

- Embossed Metal Label is made of soft metals. It can also be produced from stainless steel in special works such as elevator keys. Aluminum is used most fort he embossed metal labeling process. Since aluminum is a soft metal, it can be easily applied. Embossed metal labels can be used in many areas such as machine identification, office decorations, warning signs in almost all sectors.

Metal Label Usage Areas

Warning Labels are the most popular labels attached to a product or included in a product’s user manual. These labels warn a person of the risks associated with using the product. Warning labels can also be used in a work environment or manufacturing facility to alert workers for hazardous equipment or areas. Custom metal labels can help keep employees, staff and customers safe by warning them of hazards in the area or on a product.

Durable Warning Labels can be tear resistant if needed, or for added protection you can choose a tamper proof label material so you can see if anyone is trying to remove your labels. Metal labels are the best labels to ensure this.

Danger Labels may also be a requirement if you are shipping hazardous waste materials or if your package contains hazardous materials or if hazardous materials are present in the workplace. These labels are made to protect people from dangerous substances, chemicals and liquid.

Advantages of Metal Labels

Using metal labels can take place in your life as identification if they are used in machines and devices, and as marking if applied to other materials. This long-lasting label can be applied in different ways such as screwing, as well as bonding.

TMK Advertising Metal Label

With our TMK Advertising brand, we professionally create all your orders and requests regarding Metal Label products. We quickly complete the design, project and production process of the Metal Label products you need and realize your orders with first-class workmanship.

Metal Label Prices

You can contact us to get information about your Metal Label orders that can be used in different sizes, dimensions and usage areas and the prices to be created according to your order.